S I T E M A P

BIM

Utilization of Interoperability between Programs for Automated Drawing Production Generating Process

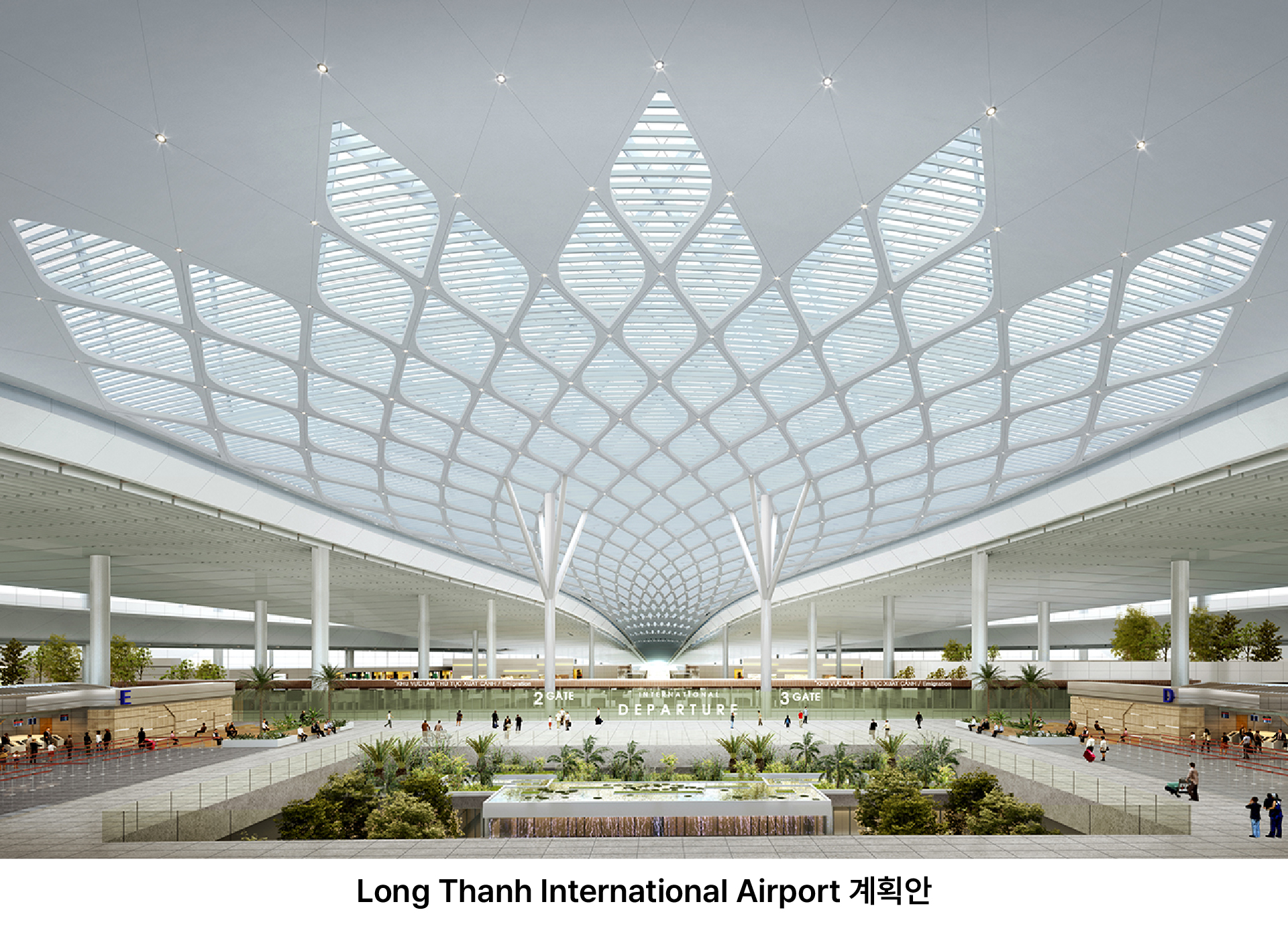

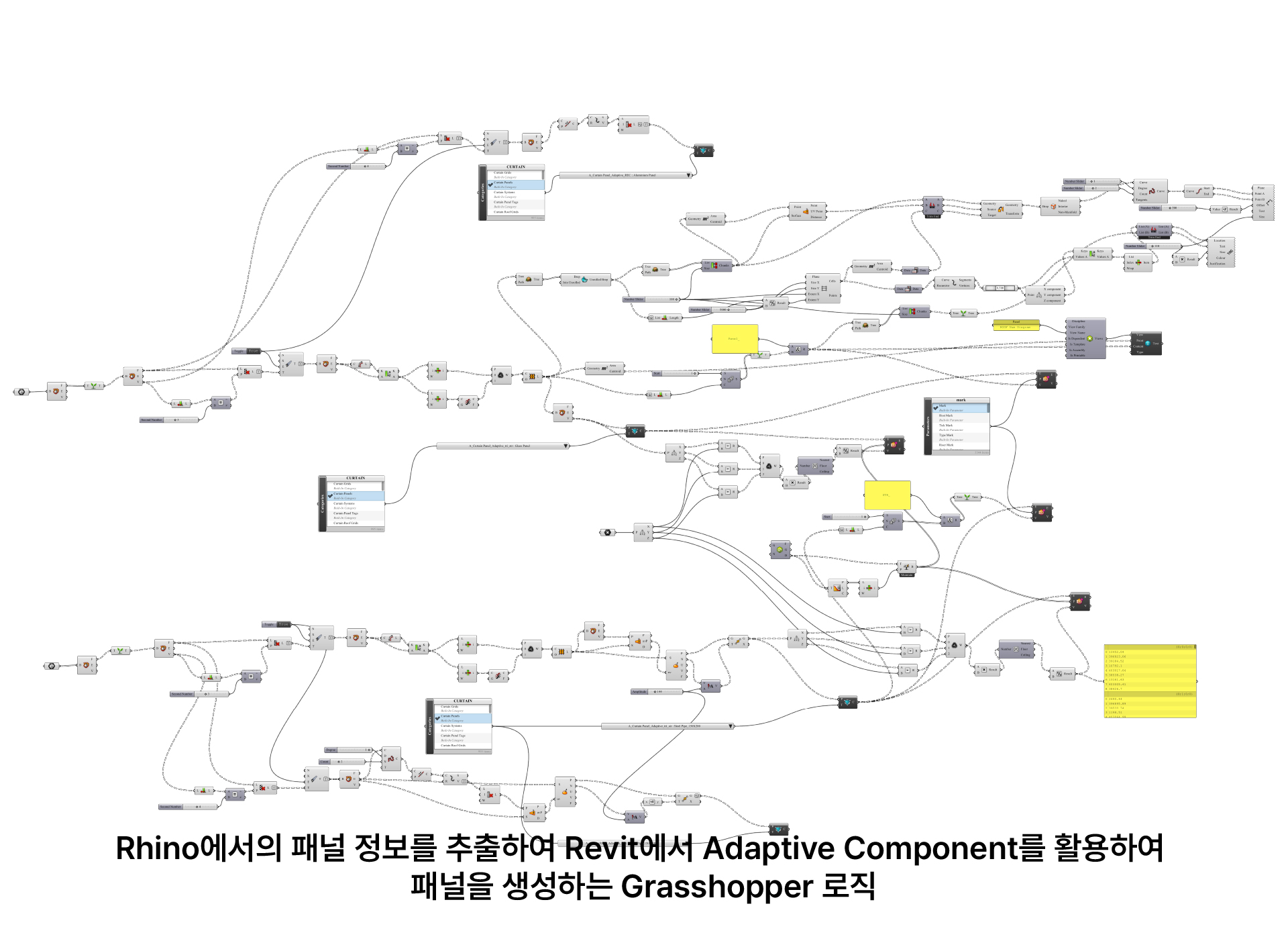

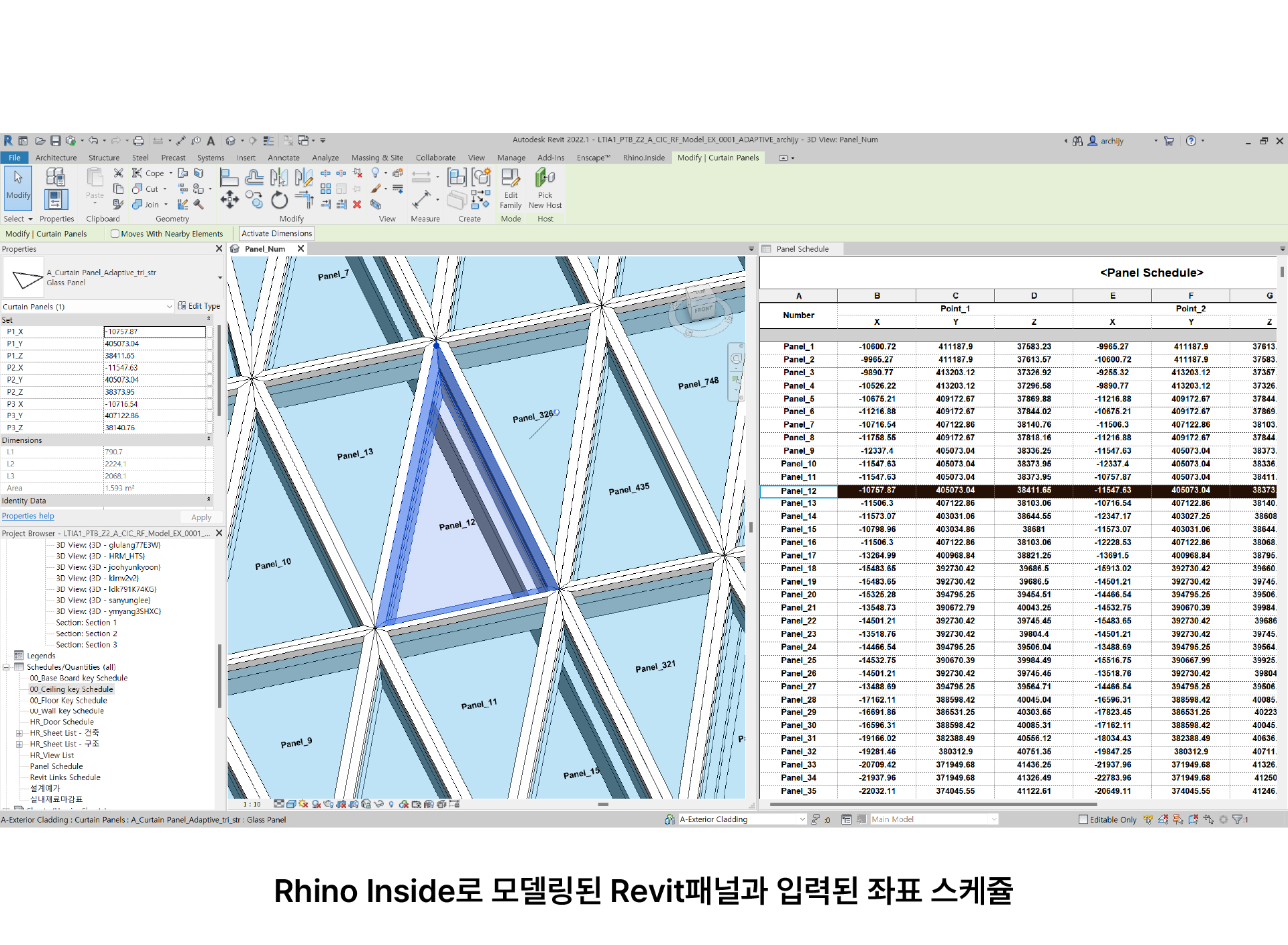

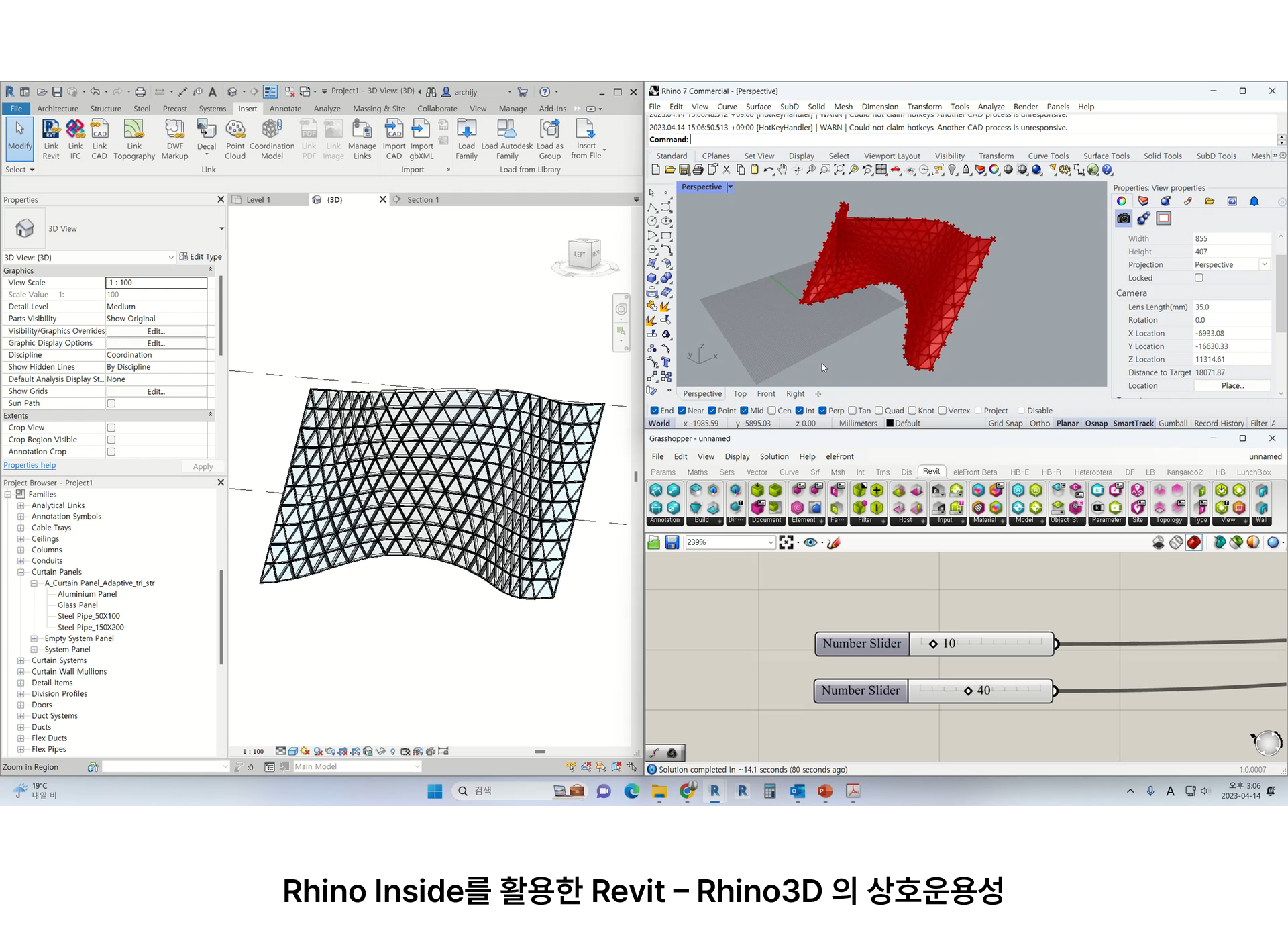

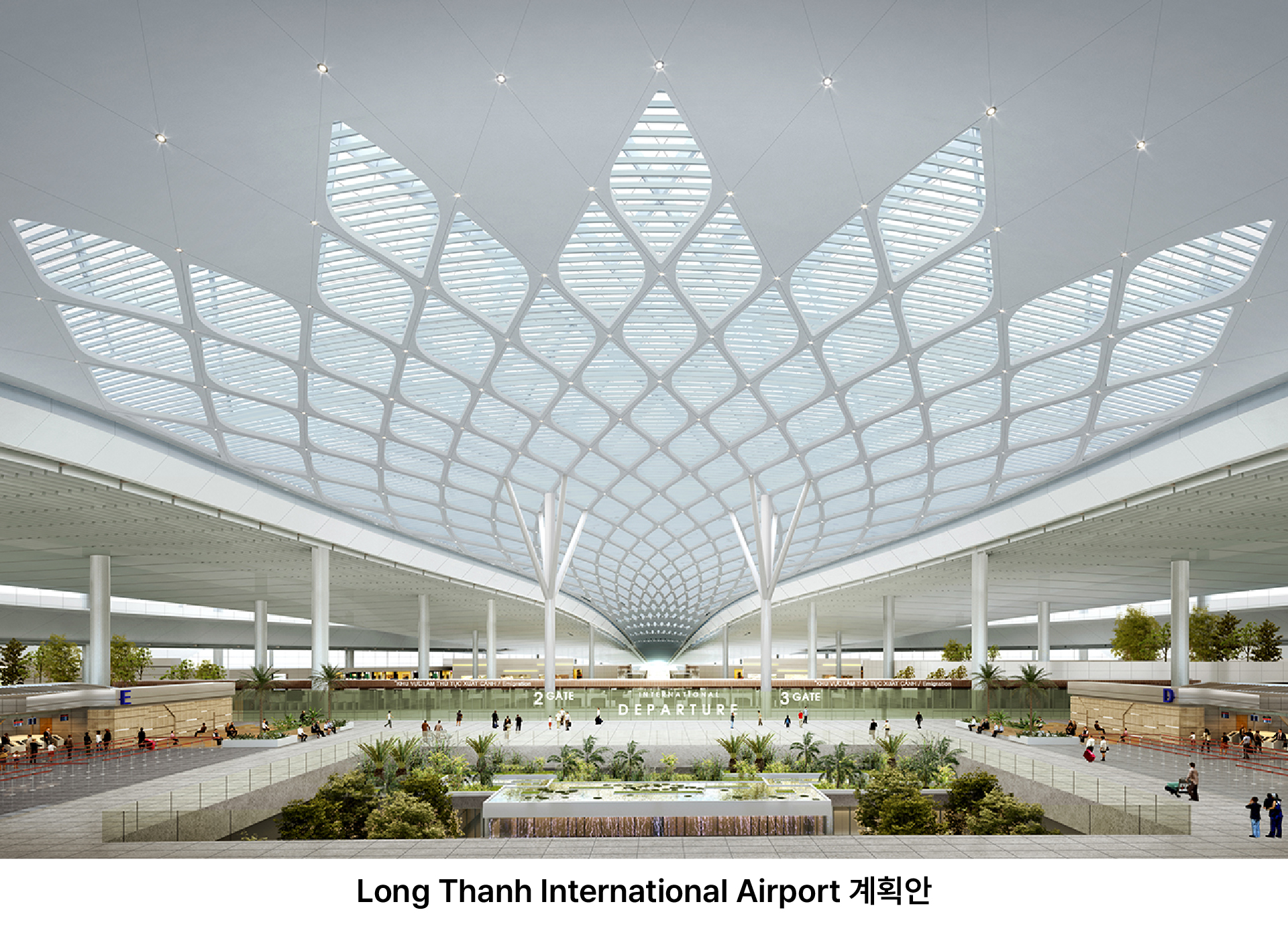

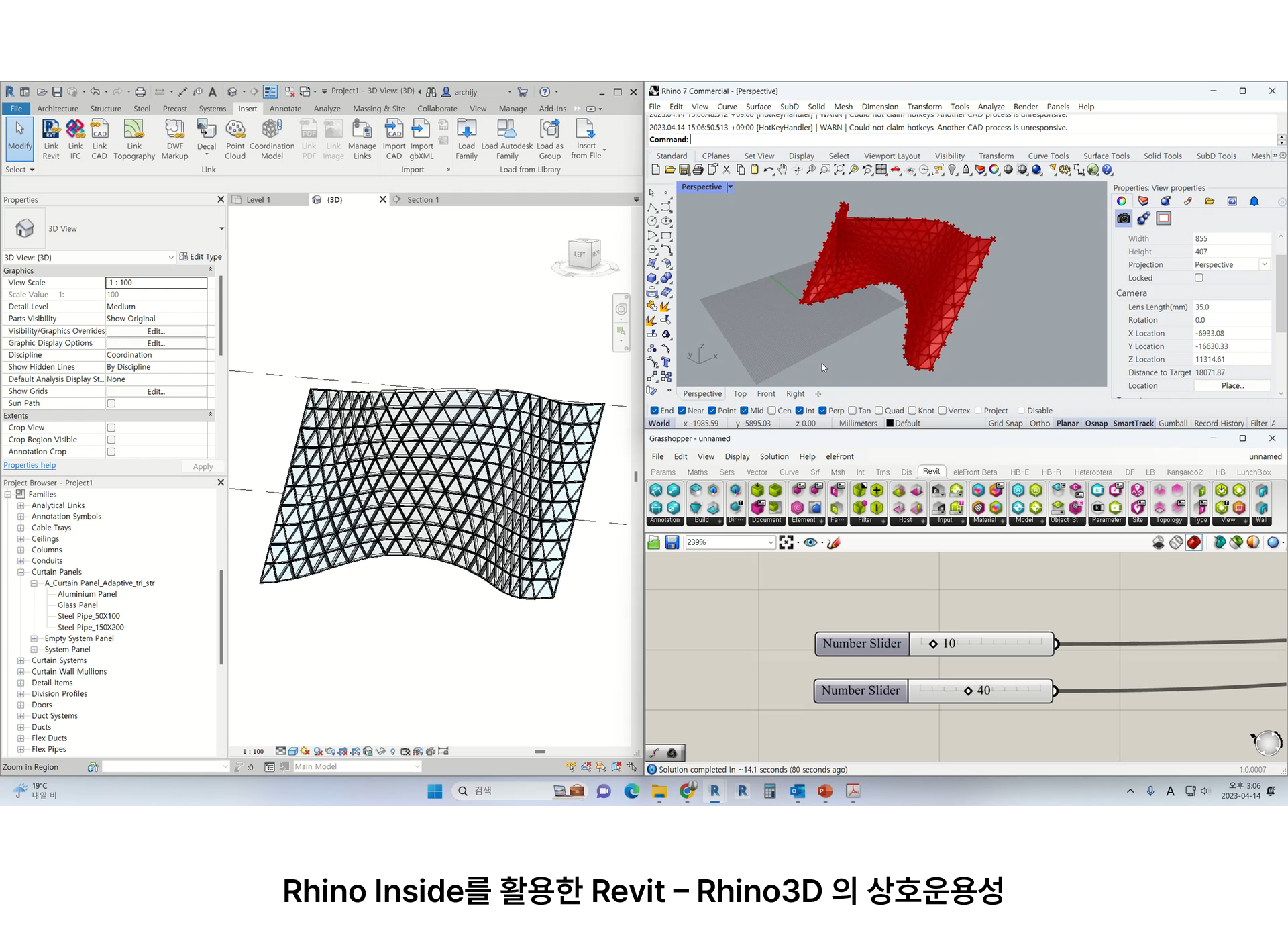

Rhino Inside is a plug-in that enables real-time integration between Rhino3D and Revit, allowing designs created in Rhino3D to be seamlessly utilized in Revit. By leveraging Rhino Inside, various architectures designed in Rhino3D can be accurately modeled in Revit, thereby enhancing the suitability of the drawings. In addition, the real-time model updates in Revit enable immediate reflection of design changes, resulting in reduced modeling time. Recently completed Long Thanh International Airport, characterized by its immense scale and irregular skylights, and incorporated Rhino Inside into its design process.

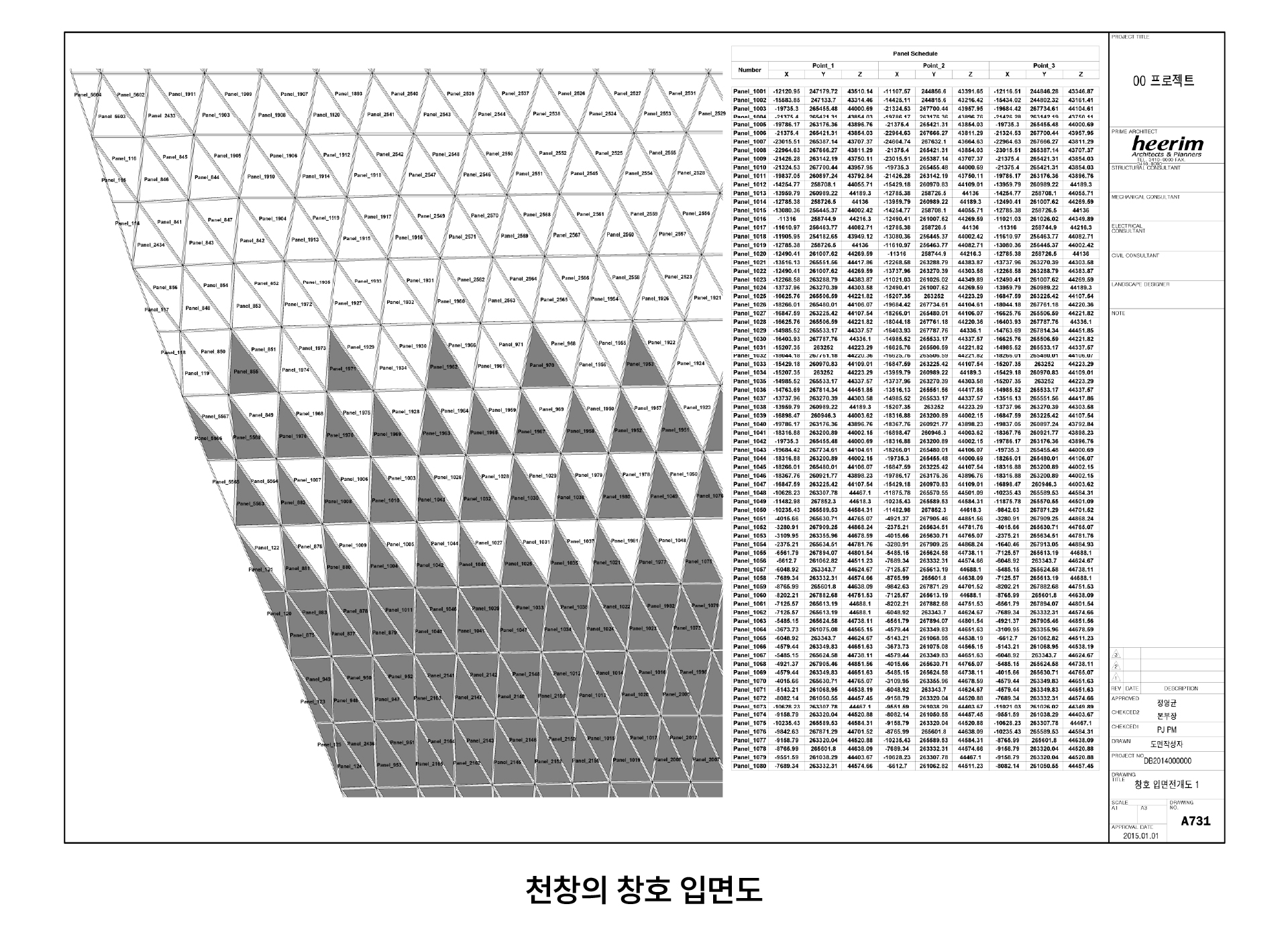

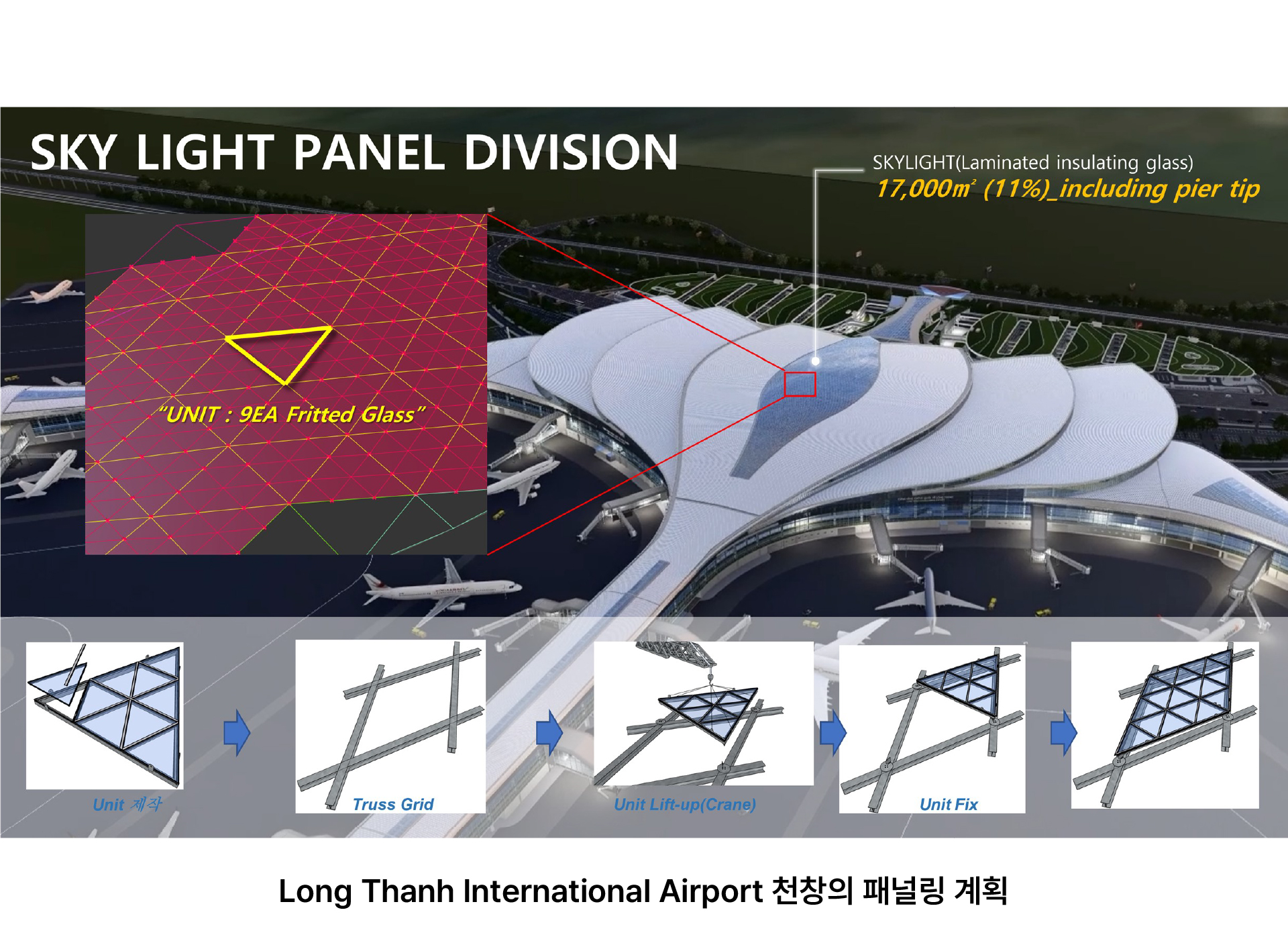

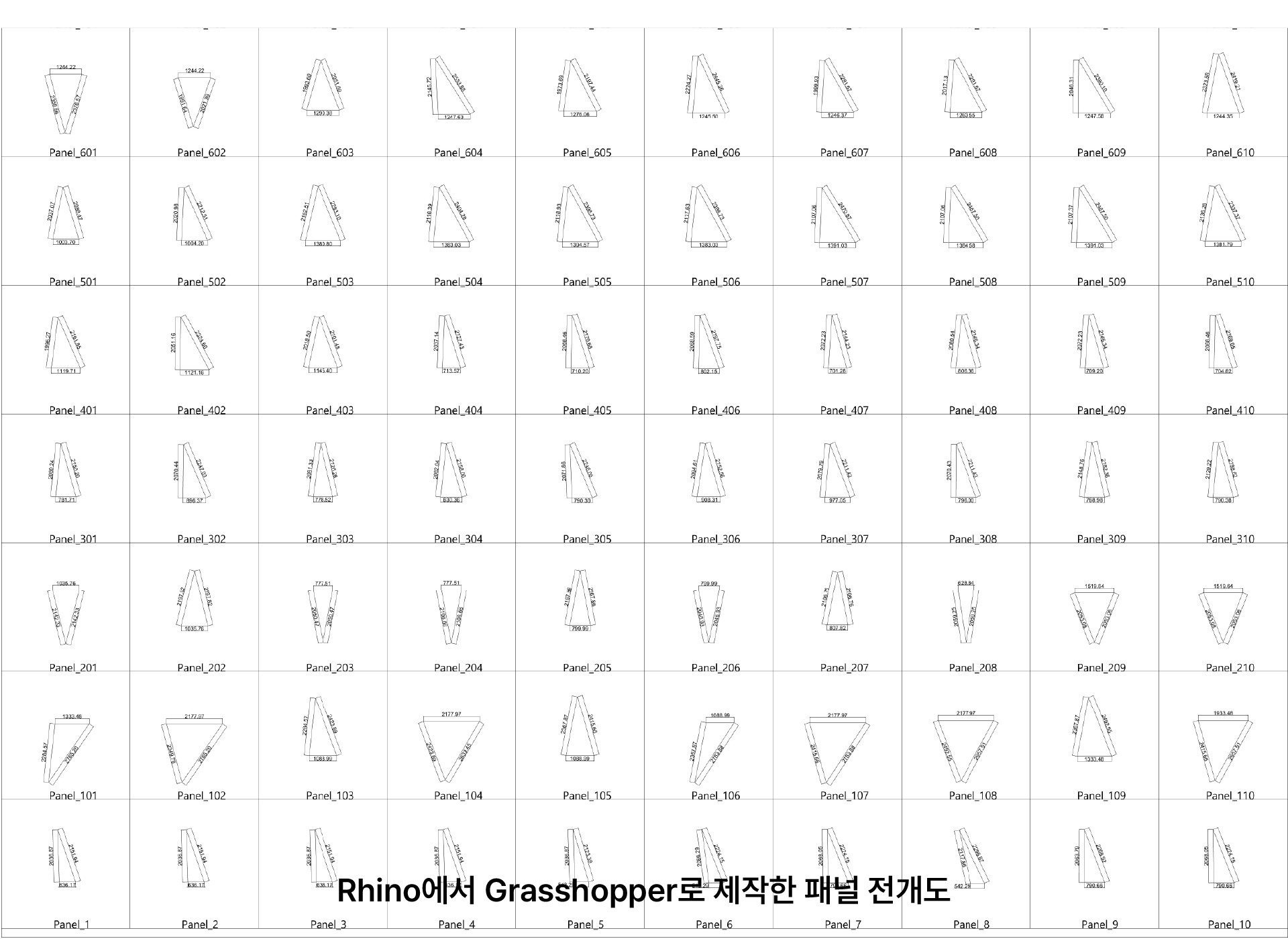

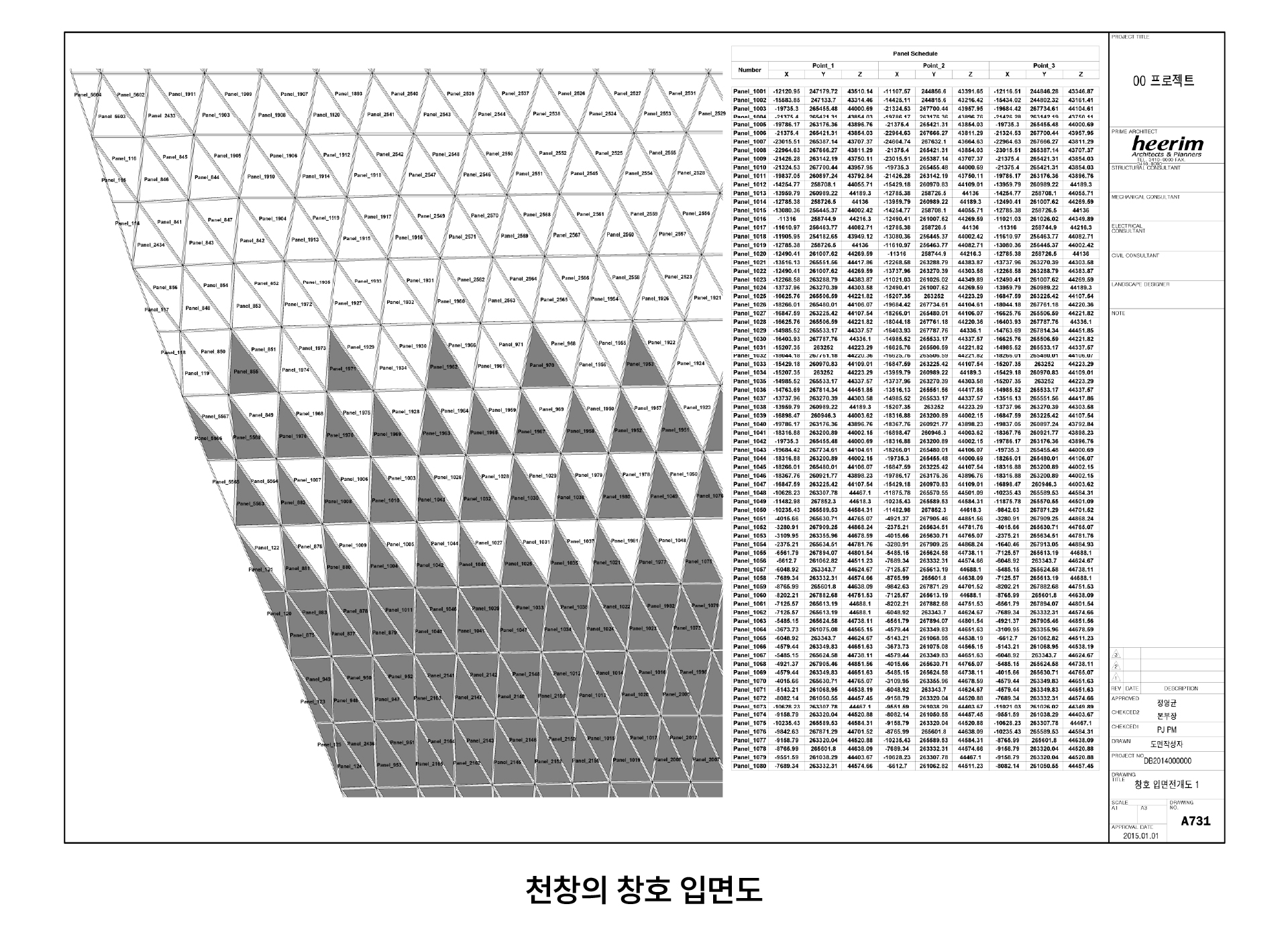

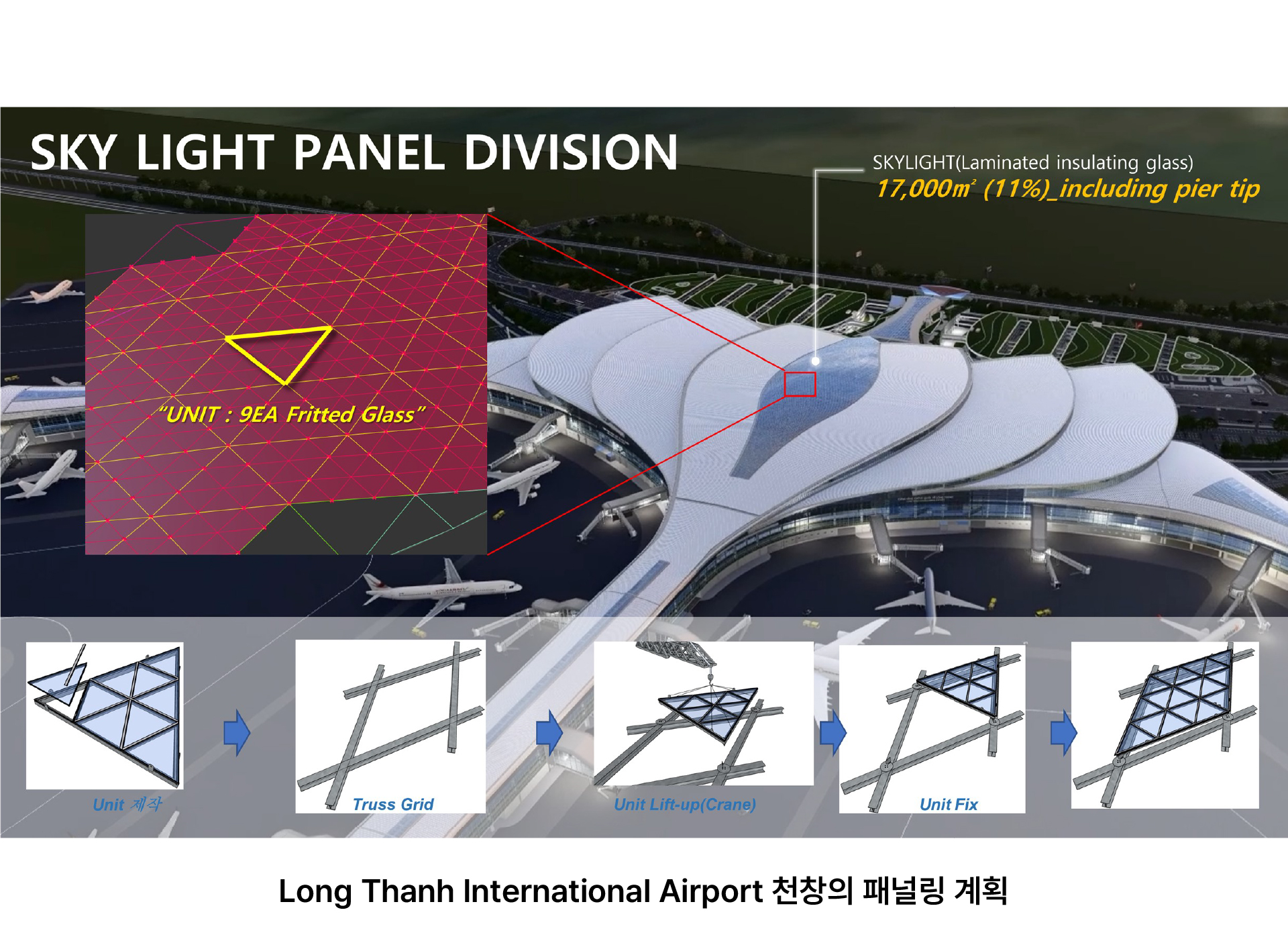

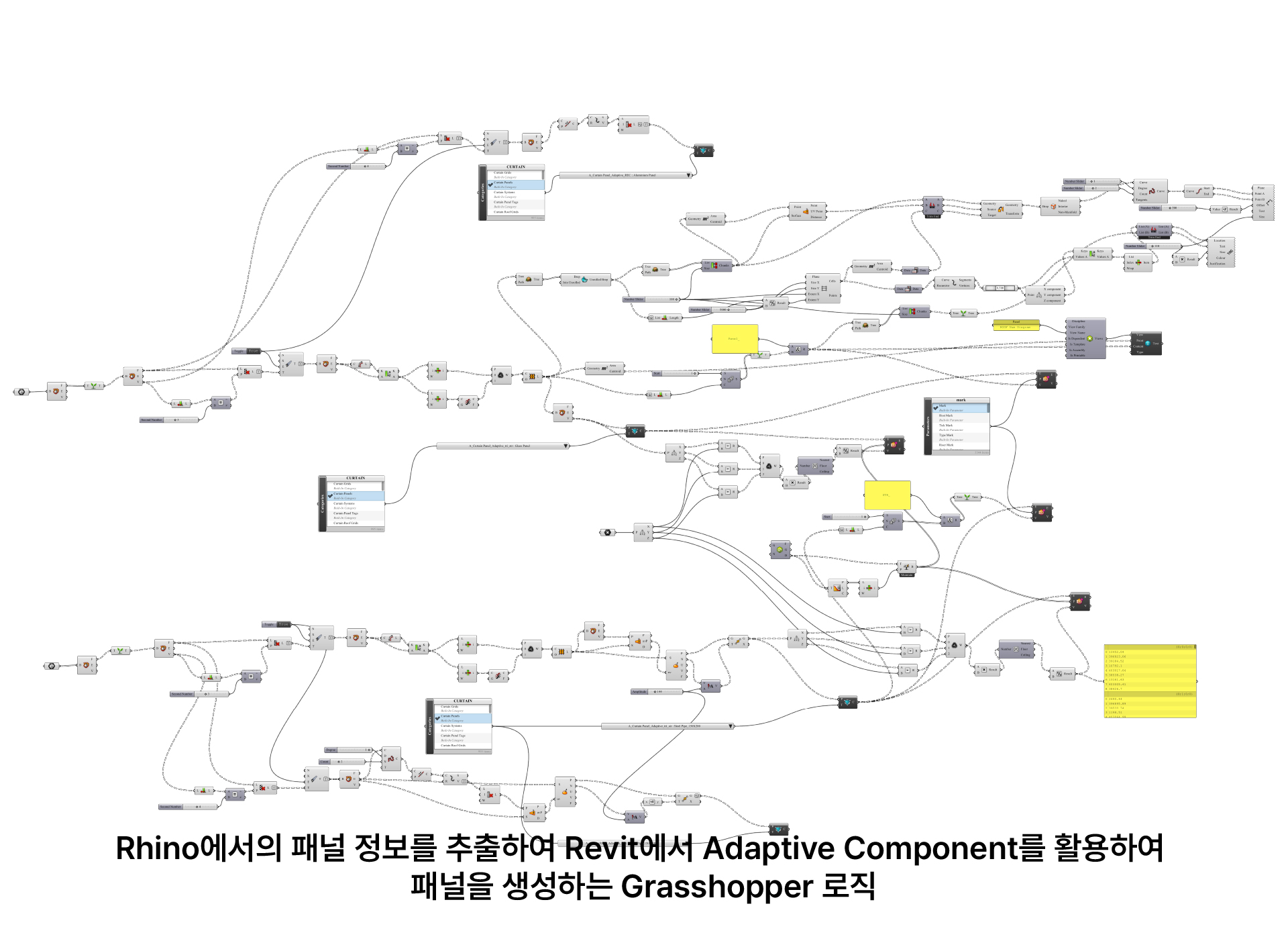

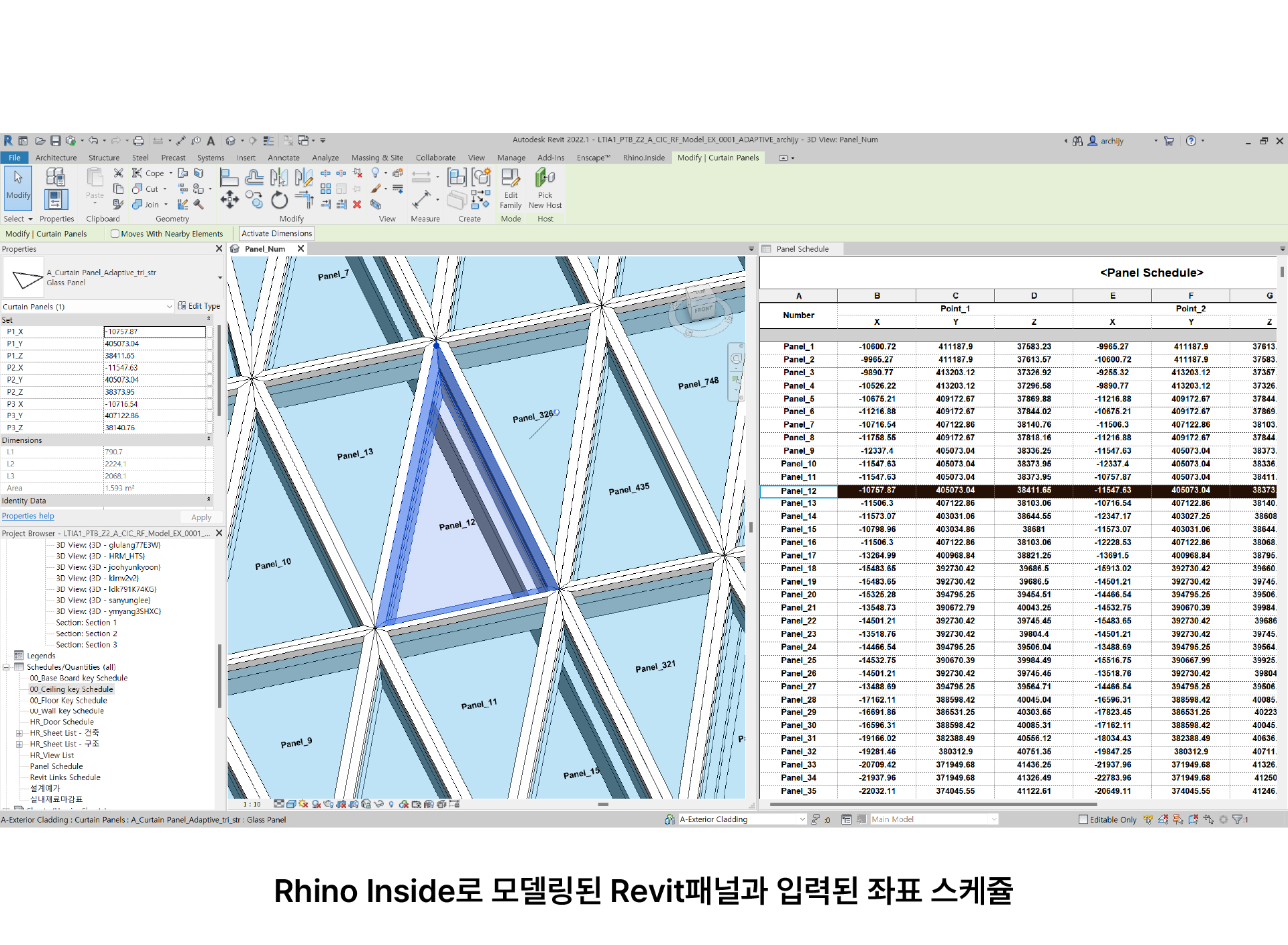

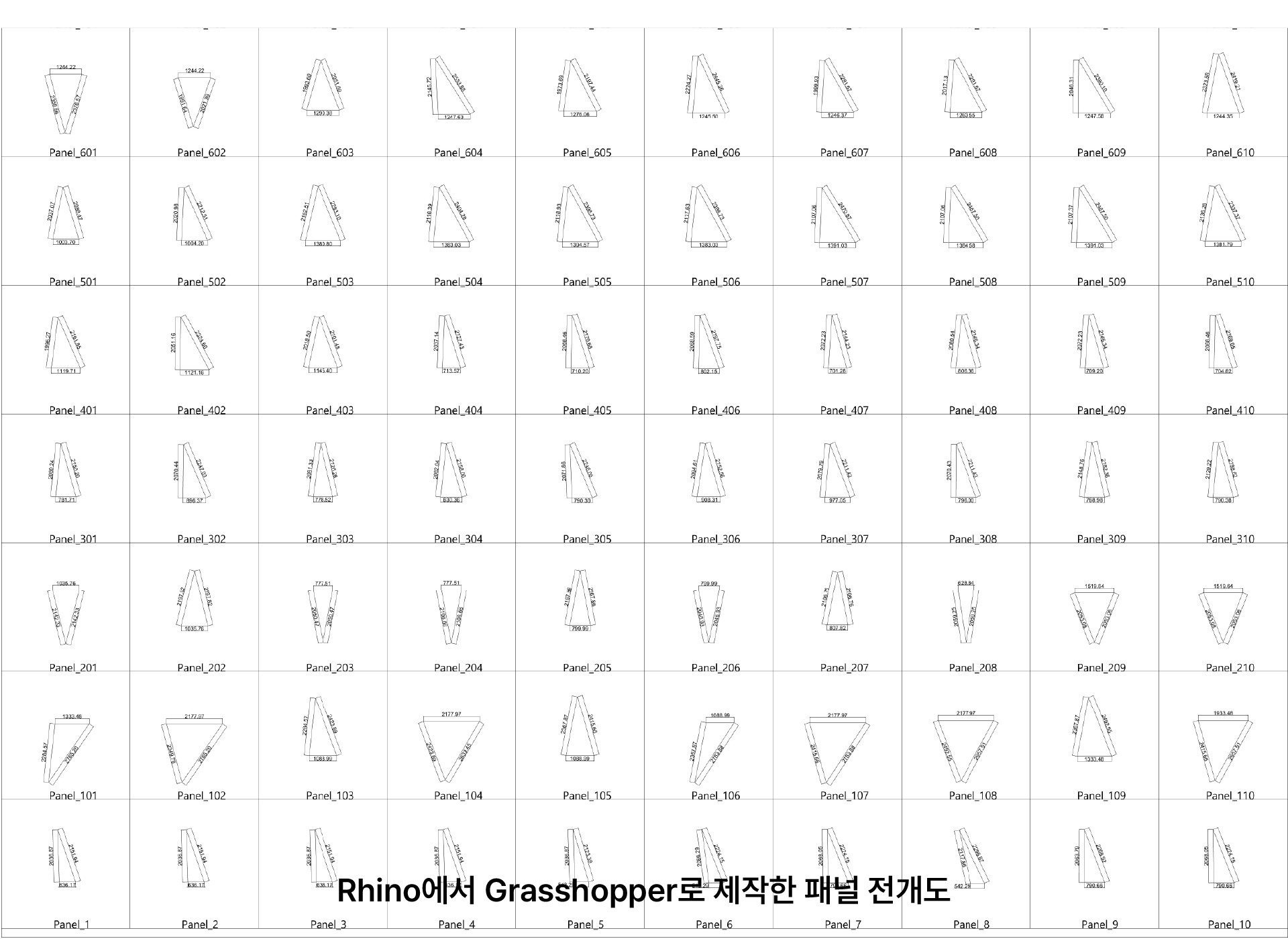

The skylights at Long Thanh International Airport have been integrated with the internal ceiling, becoming a crucial design element for both the exterior and interior ambiance of the building. Rhino Inside was utilized for precise modeling and drawing of aluminum louvers, rotated at various angles on the ceiling to create irregular-shaped skylights and effectively allow the ingress of light. Specifically, the skylights were designed with nine triangular planes forming one large triangle, supported by the underlying structure, and accurate modeling and dimensioning, as well as drawings derived from the model, were required for UNIT production. Due to the irregular nature of the skylight panels, it was essential to identify their positions and gather information for their installation. Some panels were rectangles, while most were triangles, so a Grasshopper logic was devised to differentiate and model them accordingly. This process involved extracting coordinates from the design created in Rhino3D, generating curtain wall glass and mullions, and inputting the coordinates and identification numbers of each component. This efficient procedure facilitated the swift progression from Revit modeling to inputting coordinate information for approximately 6,500 panels in just two steps. Furthermore, the coordinates and identification data from Rhino Inside could be extracted into schedules, enabling their utilization in drawings and Excel sheets. Notably, Revit presented challenges in generating development drawings; however, by synchronizing Rhino and Revit models, the functionalities of Rhino3D could be leveraged to create CAD development drawings. This process was modularized to facilitate future application in projects, aiming to enhance design quality and constructability by defining additional information for BIM implementation.